AltR&D is specialized in designing and manufacturing amplifier for infrared quantum detector (photovoltaic, photoconductor…). These detectors convert infrared radiation into electrical signal and are therefore generally used as non-contact temperature sensor. One major benefit of quantum detector over traditional temperature sensor is the very low response time (up to the nanosecond range). We use this kind of sensor for thermal characterization of materials (homogeneous, multilayer, thin layer) and contact resistances. To cover our needs, we have developed 3 series of amplifiers (resp. LF-, MF-, HF-) for different signal bandwidth (up to 100Mhz) and price ranging from 1000 to 3500 HT depending on topology, options and accessories.

| LF-series Low frequency amplifier From DC to 1 kHz | MF-series Medium frequency amplifier From DC to 10 MHz | HF-series High frequency amplifier From 1 kHz to 100 MHz |

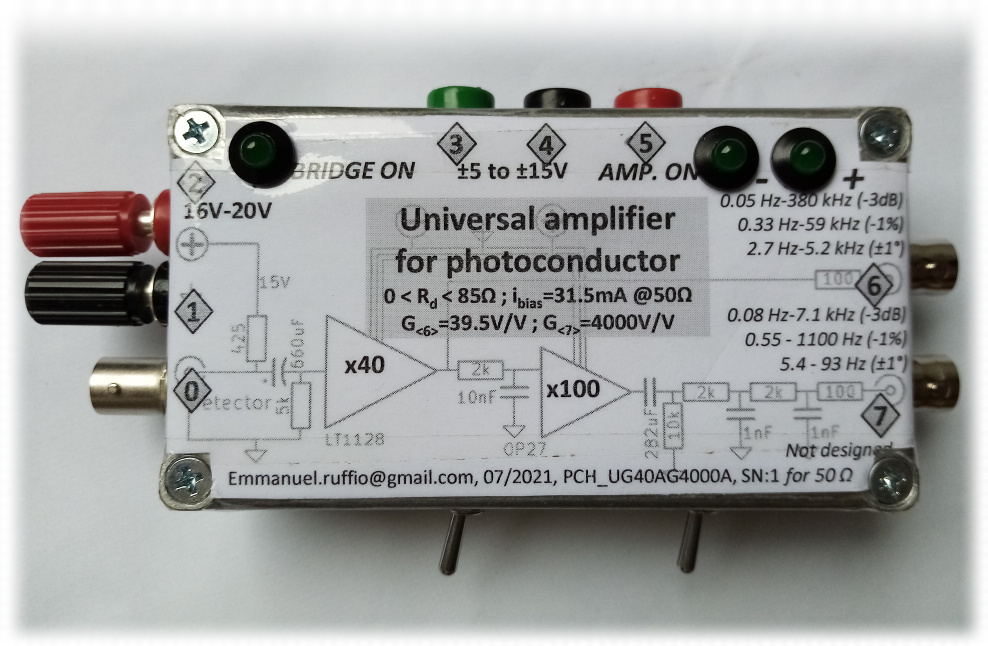

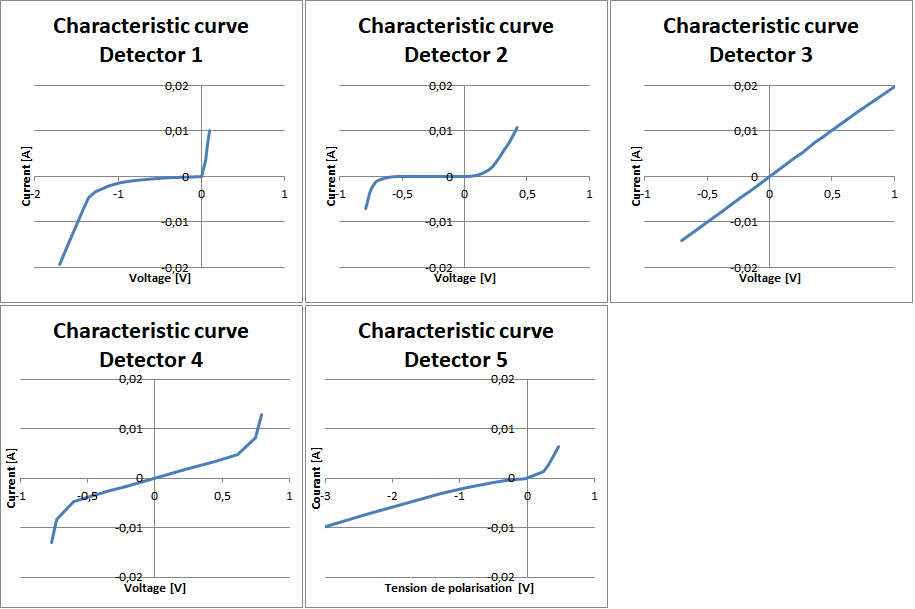

Amplifiers are custom made according to your needs (bandwidth, gain, noise…) and to your detector (type, biasing voltage/current, internal resistance…). The close match between the amplifier and the detector is the key to achieve high performance. If a low frequency amplifier may be used with different detectors, high frequency operations required a perfect adaptation of the amplifier to the detector. In our experience, infrared detectors exhibit very different behaviors (Fig.2) depending their internal nature, the manufacturer, etc… As a result, one amplifier is designed for one detector only, unless performances are not that critical.

Features

To preserve amplifier integrity, several input protections are implemented. The amplifier’s power supply is protected against reverse or invalid polarities and non-synchronized polarities. Input current limiters preserve internal capacitors from excessive in-rush current at start-up. Signal input and output are protected against ESD events and handle continuous short-circuits. However, for high speed applications, ESD protections may be reduced to limit parasitic capacitance.

A full documentation is provided with each amplifier:

- transfer function and cut-off frequencies are provided

- schematic and pcb layout are given to ease component changes

- procedure to modify amplifier parameters (bandwidth, gain, biasing voltage/current…)

If necessary and based on your feedbacks, amplifiers can be updated to better match your needs. It consists in changing some electronic components by de/resoldering them. Unless explicitly requested, adjustable components (like potentiometers…) are not used due to their tendencies to generate noise, perturbations and potential stability issue. Component replacement may be done by yourself (warranty is voided) based on schematic, pcb layout and the component kit (see amplifier options) or by Alt-RD.

For low noise applications, a battery kit is available with the proper charger.

If you are implementing your own amplifier, an amplifier kit can be provided. The kit contains a shielded box and an empty pcbs equipped with proper connectors. In option, the power supply stage is mounted in our lab.

After sales service

Nous sommes opposés à toute forme d’obsolescence de nos produits. Si vos besoins évoluent, un amplificateur peut être modifié/ajusté après sa fabrication. Le forfait modification est à partir de 200€ HT. Nous pouvons également vous fournir les composants pour vous permettre de réaliser vous mêmes ces modifications selon nos instructions (annule la garantie).

Sauf mention expresse de votre part, nous conservons dans notre base de données la liste des composants utilisés lors de l’assemblage de chaque amplificateur afin de vous assister lors des éventuelles mises à jour ou réparations.

En cas de panne ou de performances visiblement dégradées, nous proposons un forfait réparation de 200€ HT pour identifier les causes de ces défaillances et réaliser les réparations nécessaires.